Products

additives

cross linking agent

nitro cellulose

anti-corrosion

floor hardener

phosphate esters

anti tannin

initiator

refrigerant

conductive carbon black

micronized wax

surfactant

coupling agent

microspheres

wax

Anti-Corrosion & Anti-Tannin

Corrosion inhibitors and tannin inhibitors are used in paints and coatings to enhance durability and appearance. Corrosion inhibitors prevent the oxidation of metals, extending the lifespan of structures and machinery, while tannin inhibitors counteract the effects of tannins in wood, preventing discoloration and degradation in finishes, particularly for tannin-rich species.

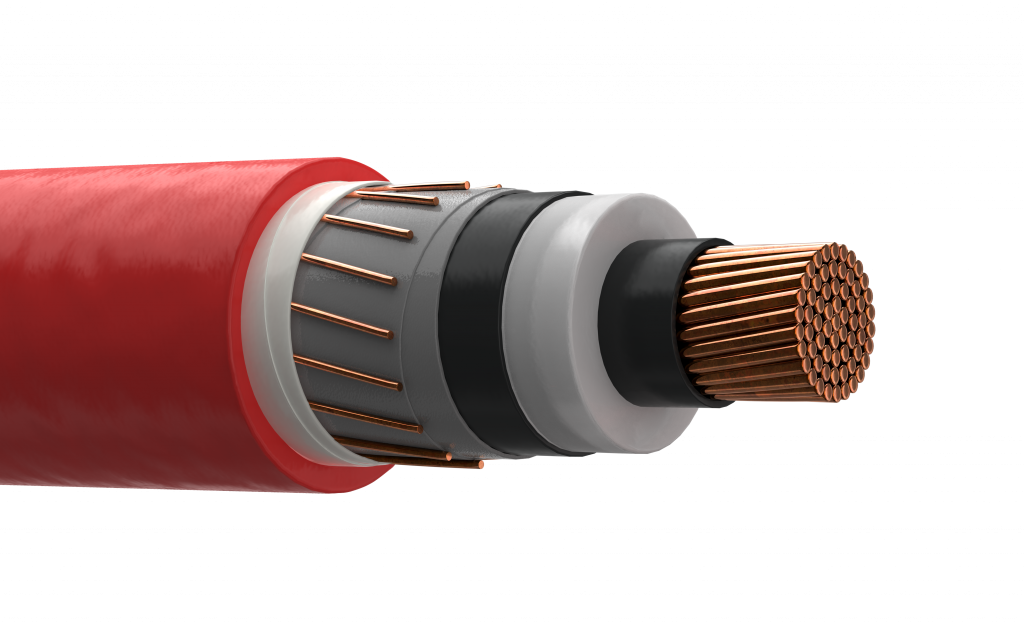

Conductive Carbon Black

Used in coatings, plastics, and rubber, because it improves conductivity, which is essential for applications like electrostatic discharge (ESD) protection, electromagnetic interference (EMI) shielding, and even in batteries, footware, and flooring. Additionally, it can enhance the mechanical properties and durability of the material while providing a black color for aesthetic purposes.

Coupling Agent

Work as a bridge to incorporate inorganic and organic material which enables good dispersion of inorganic filler into polymer for many applications composite materials, paint dispersion, plastic compound, rubber compound.

Cross-Linking Agent

Create chemical bonds between polymer chains, resulting in a more rigid and durable material. This process, known as cross-linking, enhances the mechanical properties and resistance to heat, chemicals, and solvents. Used as an agent to link rubber within wire & cable, technical rubber goods, or footwear industries.

Floor Hardener

Applications as an aqueous suspension of silica nanoparticles that enhances durability and strength. It is commonly employed in the construction and flooring industries for its ability to improve surface hardness and resistance to wear and chemical damage.

Initiator

Polymerization initiator in the production of plastics and other chemical reactions. It decomposes when heated or in the presence of certain catalysts, releasing free radicals that start polymerization. Its strong oxidizing properties enhance reactions, making it valuable in industries like coatings, inks, and paints.

Microspheres

Applications as an aqueous suspension of silica nanoparticles that enhances durability and strength. It is commonly employed in the construction and flooring industries for its ability to improve surface hardness and resistance to wear and chemical damage.

Nitro Cellulose

Component in many paints and coatings, as it forms a strong, flexible film that dries quickly, ensuring efficient application. Its unique properties enhance adhesion to surfaces while providing a smooth, glossy finish, making it particularly popular in automotive paints and wood finishes.

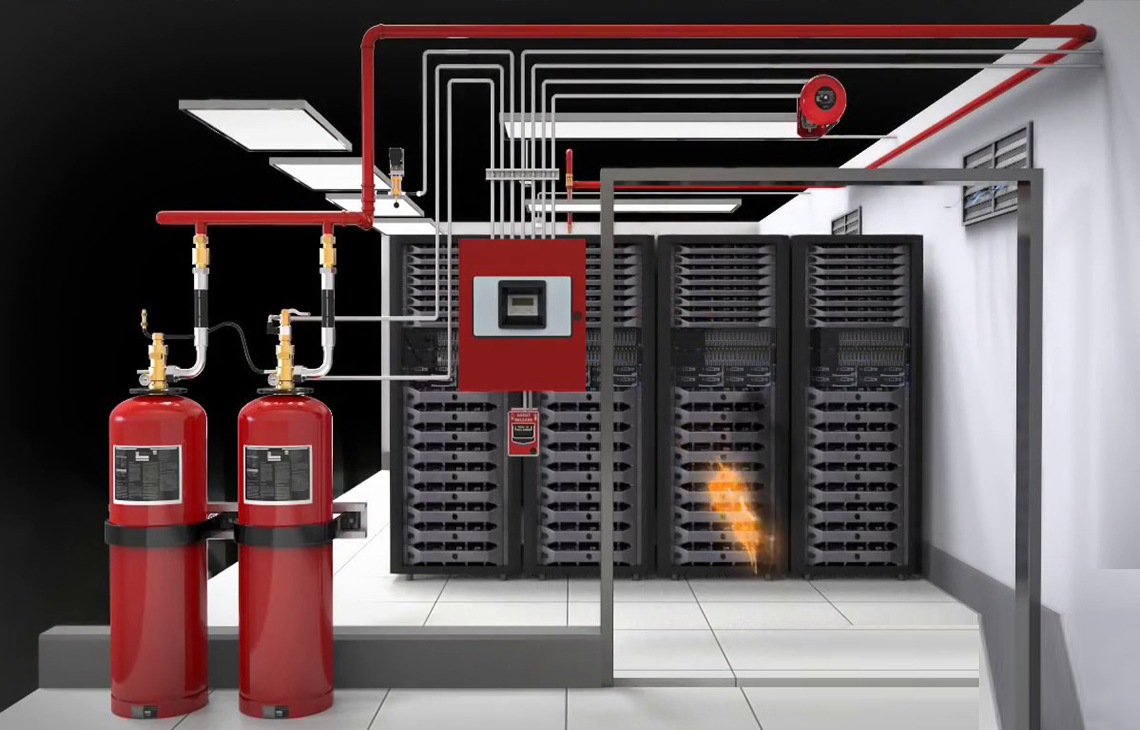

Refrigerant

absorbing heat from a warmer environment through a process of evaporation and then releasing that heat to a cooler environment through condensation. Uses include HVAC systems, refrigeration, and heat pumps.

Surfactant

reduce surface tension between two immiscible liquids or between a liquid and a solid. This property enables them to improve the wetting, emulsification, and foaming properties of various substances, making them essential in detergents, cosmetics, and industrial applications. Used in inks, paints, and coatings

Wax & Micronised Wax

High quality waxes produced in Europe with broad field of industrial applications like coatings, powder coatings, printing inks, lacquers, plastics, masterbatches, release agents, lubricants, wax emulsions, wax dispersions and more.